Compared with the roof, which can be renovated and rebuilt with waterproof layer, the underground waterproof project can be regarded as a one-time permanent project. The leakage repair and treatment of the basement roof, especially the planting roof, is the most difficult among the difficulties. How to avoid leakage of the basement roof as much as possible is a problem that every waterproof person should seriously consider. This article introduces the design principle, material composition and characteristics of the integrated drainage and prevention system of Weidun planting roof, and describes the construction process, precautions and application effects of the system in detail through specific engineering cases.

1 Working principle and composition of the integrated drainage and prevention system of planting roof

1.1 Working principle of the integrated drainage and prevention system of planting roof

There are many reasons for the leakage of planting roof, such as the quality problem of waterproof layer construction, the quality problem of waterproof material itself, structural deformation, plant root puncture, etc. In the final analysis, it is nothing more than the failure of the self-waterproof structure roof and waterproof layer of the building, and sufficient water on the roof seeps into the basement. The original intention of the design of the Weidun planting roof drainage integrated system is to minimize the failure of the waterproof layer while controlling the water accumulation on the roof. Even if the waterproof layer fails, there is no water accumulation on the roof or the amount of water accumulation is insufficient, and there will be no particularly serious leakage.

The Weidun planting roof drainage integrated system combines the concept of integrated waterproofing with the concept of siphon drainage. According to the control mechanism of the intelligent control system, the siphon drainage principle is used to quickly absorb the rainwater on the roof; it can also be combined with the sponge city concept to achieve the temporary accumulation of rainwater on the roof. When the pressure of the municipal rainwater pipe is too high, the peak drainage is staggered to reduce the drainage pressure of the municipal pipe network.

1.2 Composition of the integrated drainage and waterproofing system for planted roofs

The integrated drainage and waterproofing system for planted roofs of Weidun mainly consists of a waterproofing system, a drainage system and various management measures.

1.2.1 Waterproofing system

The integrated drainage and waterproofing system for planted roofs of Weidun can be customized according to customer needs. The commonly used waterproofing system consists of non-curing rubber asphalt waterproofing coating and its similar products, ultra-fiber polymer membrane-based double-sided self-adhesive root-resistant waterproofing membrane, and polymer special-shaped waterproofing board.

1) Cold-applied non-curing rubber asphalt waterproofing coating

The cold-applied non-curing rubber asphalt waterproofing coating is a two-component reactive waterproofing coating. Component A is mainly composed of terminal hydroxyl liquid rubber and modified asphalt as a prepolymer, which reacts with the cross-linking curing system of component B to generate a highly compatible waterproofing coating. The performance index of this coating meets the requirements of JCT2428-2017 "Non-curing Rubber Asphalt Waterproof Coating". On the basis of the standard requirements, the heat resistance is increased to above 80℃, and it can be constructed without heating. It has the excellent composite effect of traditional hot-melt non-curing rubber asphalt waterproof coating, overcoming its construction difficulty, high safety hazards of high-temperature construction, and high energy consumption.

2) PPS ultra-fiber polymer film-based self-adhesive root-puncture-resistant waterproof membrane

PPS ultra-fiber polymer film-based self-adhesive root-puncture-resistant waterproof membrane is a root-puncture-resistant waterproof membrane made of ultra-fiber polymer film as the base material, covered with modified asphalt root-puncture-resistant self-adhesive adhesive, and coated with silicon isolation film on the lower surface. The performance index meets the relevant requirements of GBT35468-2017 "Root-puncture-resistant waterproof membrane for planted roofs". Compared with traditional wet-laid self-adhesive waterproofing membranes, PPS microfiber polymer membrane-based self-adhesive root-piercing waterproofing membranes do not bulge or wrinkle, have higher tear resistance, and the membrane base and rubber material are not separated. The joints are well sealed, which can ensure the waterproof quality.

3) Polymer special-shaped sheet waterproof board

Polymer special-shaped sheet waterproof board is the core product of the Weidun planting top plate drainage integrated system. It consists of two parts: polymer special-shaped sheet and anti-collapse microfiber water filter cloth, which has both waterproof and drainage functions.

Polymer special-shaped sheet is made of polyethylene (HDPEILDPE) as the main raw material. It is a conical protrusion-shaped sheet made by extrusion and calendering. The thickness is >1.2 mm and the height is >14 mm. It implements GB 18173.1-2012 "Polymer Waterproof Materials Part 1: Sheet Materials" special-shaped sheet waterproof material standard. It adopts a unique welding reserved edge design, so that the polymer special-shaped sheet waterproof board can achieve long and short side welding construction during the top plate laying process to form an overall drainage layer.

The fiber filaments of the anti-collapse microfiber water filter cloth adopt a unique thermal bonding process, and the fiber filaments will not be displaced. It has the characteristics of high strength, high filtration, and not easy to clog. The anti-collapse microfiber water filter cloth has a tensile strength of more than 350N/(5cm) in both the horizontal and vertical directions at an elongation of 2%, which can ensure that the polymer special-shaped waterproof sheet will not collapse after being covered with soil; the equivalent aperture of the water filter cloth is 80~200m, which can effectively avoid the poor water filtration effect caused by silt blockage, and its water filtration efficiency is more than 2 times that of ordinary needle-punched non-woven fabrics. According to the test results of the soil covering experiment, the drainage cross-sectional area of ordinary polyester non-woven fabrics is reduced by more than 50% due to the collapse of the non-woven fabrics after being covered with soil; while the drainage cross-sectional shape of the anti-collapse microfiber water filter cloth is intact after being covered with soil, and the drainage cross-sectional area can be maintained at more than 95%.

The polymer special-shaped waterproof sheet has stable physical and mechanical properties, good durability and anti-aging ability; it has excellent heat resistance and cold resistance, and can be used in the north and south regions; it has good impact resistance and compressive strength of more than 450kPa; the special conical boss structure has good pressure bearing capacity and stress dispersion, and is not easy to be flattened; the drainage cross-sectional area can reach 96.8cm, and the drainage performance is good; the welding process is adopted, and the weld peel strength is>3.0N/mm, which can ensure that the polymer special-shaped waterproof sheet forms a closed whole, and has both drainage function and waterproof function, truly achieving integrated drainage.

1.2.2 Drainage system

The drainage system of the Weidun planting roof drainage integrated system is mainly composed of polymer special-shaped waterproof sheets, rainwater collection pipes, auxiliary siphon tubes and supporting fully automatic intelligent control systems.

1) Rainwater collection pipes

The rainwater collection pipe is also called a weightless organized drainage system. Most of the weightless organized drainage systems on the market are first arranged on the roof by gluing or other methods in the vertical and horizontal directions according to the design, and then the concave and convex drainage boards are laid. The concave and convex drainage boards are disconnected in the rainwater collection pipe area.

The Weidun planting roof drainage integrated system first lays polymer special-shaped waterproof sheets, and then lays rainwater collection pipes at the overlapping parts of the waterproof sheets to ensure the integrity of the waterproof sheets. After the rainwater collection pipe is laid, the surface is covered and sealed with microfiber water filter cloth to prevent the covering soil from directly entering the rainwater collection system and causing blockage.

2) Auxiliary siphon tubes and fully automatic control system

The auxiliary siphon tubes and fully automatic control system are innovative measures of the integrated siphon drainage system of the Weidun planting roof. After the rainwater collection pipes are laid out in a mesh, 3 to 5 rainwater collection points per 10,000 m' are laid out on the roof as the starting points of the closed auxiliary siphon tubes. Each point operates independently and is connected in series. The fully automatic control system can adjust the conditions for the generation of siphons, control the siphon drainage time and drainage volume according to customer needs, so as to prevent roof leakage or the infiltration, stagnation, storage and drainage of urban precipitation in the sponge city.

The auxiliary siphon tubes and fully automatic control system can reasonably configure the drainage plan according to the rainfall conditions, the drainage capacity of the urban rainwater pipe network, the drainage capacity of the watershed, the planting soil planting needs, etc., to achieve the purpose of peak discharge and water conservation.

The system is equipped with a rainwater purification, recycling and irrigation system, which can test the moisture, temperature, pH value, nitrogen, phosphorus and potassium content in the soil, use water as a carrier, adjust various values, ensure the normal growth of plants, and realize the purification and recycling functions of the sponge city. The overall system can also achieve regional data macro-control through the Internet of Things and data sharing, and has strong scalability.

1.2.3 Various management measures

1) Preliminary on-site investigation and design by a professional skills team

A good product and system must have corresponding excellent management measures. The integrated system of top plate drainage and prevention of Shengwei Shield planting is equipped with a strong technical team and a professional design team. Preliminary project investigation, multiple investigation methods are used to implement infrared scanning of the top plate and modeling, and to identify water accumulation points and drainage outlets. It is tailored according to the on-site investigation results and the specific conditions of each project, carefully designed, ingeniously constructed, and the quality is more guaranteed.

2) Mid-term standardized construction operation

Weidun Company has a professional construction team and provides standardized operation manuals. All construction personnel are certified after systematic training and professional construction operations, and complete machinery and auxiliary materials are provided to ensure the construction quality of Weidun's integrated system for drainage and drainage prevention.

3) Later stage improvement of guarantee system

Weidun Company's Engineering Management Department assigns special personnel to inspect each project, and report and handle problems in a timely manner; the company establishes a labor and material management library to archive photos and video materials of the construction process to ensure that the entire construction process can be traced.

2.Technical advantages and innovations of the integrated system for drainage and drainage prevention of planting roofs

2.1 Drainage and drainage integration, optimized structural levels

Weidun's integrated system for drainage and drainage prevention of planting roofs optimizes the structural levels of traditional planting roofs, perfectly combines waterproofing and drainage, removes concrete structural levels such as leveling layer, slope layer, isolation layer, etc., reduces some processes, reduces the risk of waterproof layer damage caused by process handover, shortens the construction period by 1/3, reduces structural load, and improves the cost performance of the entire project.

2.2 Really realized siphon drainage

For planting roofs, many siphon drainage systems have been launched on the market. But strictly speaking, these siphon drainage systems should be called weightless organized drainage systems.

There are three necessary conditions for the so-called siphon. The first is the difference in high and low liquid levels, the second is that there is continuous water or liquid inside, and the third is the most difficult to control, that is, the pipe must be sealed. Most of the so-called siphon drainage systems on the market not only have dense water inlet holes at the bottom of the rainwater collection pipe, but also usually have a vent pipe connected to the atmosphere at the intersection of the collection pipe, which does not meet the necessary conditions for siphon generation.

The Weidun planting roof drainage integrated system uses on-site surveys to determine the lowest position of the roof, and then arranges auxiliary siphon drainage pipes according to the specific conditions on site to truly realize siphon drainage.

2.3 Integrating multiple functions such as rainwater collection, utilization, discharge and soil monitoring

The integrated drainage system of Weidun planting roof can realize flexible allocation of rainwater retention time (the adjustable time is usually 2~10h) through intelligent control, combined with sponge city supporting facilities, water storage and water retention, and truly achieve peak drainage and reduce the drainage pressure of urban municipal pipe networks.

Equipped with different rainwater reuse and purification facilities and equipment, the secondary recycling of rainwater can be realized, which is particularly important in the water-scarce northern region. The integrated drainage system of Weidun planting roof can not only self-monitor and adjust the collection and utilization of rainwater, discharge volume and discharge time, but also monitor soil moisture content, pH value, soil fertility, etc., to realize the function of full control of a system.

3 Application cases of integrated drainage system of planting roof

3.1 Project overview

China Railway Construction Jiangmen Headquarters Base Project is a comprehensive large-scale development project, covering an area of 168,733 m², with a total construction area of 530,000 m² and a total construction area of approximately 700,000 m². The currently designed and constructed part is China Railway Construction Jiangwan International (Phase I), with a total construction area of about 198,700 m², of which the above-ground construction area is about 142,700 m² and the underground construction area is about 56,000 m². There are 12 high-rise residential buildings, equipped with a basement, supporting kindergartens, community rooms, etc.

This project started in October 2020 and passed the completion acceptance in December 2023. Weidun Company is involved in the drainage and waterproofing construction of the basement top plate of the residential part of the project, including the installation of supporting systems, etc., with a total waterproofing area of about 55,400 m².

3.2 Planting top plate greening form and drainage structure

The top plate greening of this project adopts a garden-style planting form, carefully selecting plant species, quantity, and configuration, focusing on plant diversity and ecological value, and how to improve the overall environmental quality of the community and the quality of life of residents through greening. The top plate has a soil thickness of 1.5m, and the greening form and plant selection are relatively complex, and the requirements for top plate waterproofing and drainage are relatively higher.

The waterproof layer of the planting roof of this project is directly constructed on the concrete base by coating and rolling. A polymer special-shaped waterproof sheet is constructed on the waterproof layer, and rainwater collection pipes, auxiliary siphon tubes and their control systems are arranged to form organized drainage. According to the preliminary on-site investigation and the design data provided by the project, combined with the original rainwater discharge design of the residential part, a total of 8 outlets are set in the overall drainage direction, which are connected to the water collection module or the municipal rainwater pipe through pipes. The structural hierarchy, section and plane diagram of the planting roof system are shown in Figure 1-3.

The waterproof layer of the planting roof of this project is directly constructed on the concrete base by coating and rolling. A polymer special-shaped waterproof sheet is constructed on the waterproof layer, and rainwater collection pipes, auxiliary siphon tubes and their control systems are arranged to form organized drainage. According to the preliminary on-site investigation and the design data provided by the project, combined with the original rainwater discharge design of the residential part, a total of 8 outlets are set in the overall drainage direction, which are connected to the water collection module or the municipal rainwater pipe through pipes. The structural hierarchy, section and plane diagram of the planting roof system are shown in Figure 1-3.

3.3 Construction process

The construction process of the integrated drainage system of the planting roof of this project is as follows: acceptance and cleaning of the base → shot blasting of the garage roof → treatment of the water collection point → waterproof construction (preparation of cold-construction waterproof coating → treatment of detailed nodes → scraping and coating of cold-construction waterproof coating → simultaneous paving of self-adhesive root-resistant waterproof membrane on large surfaces) → drainage layer construction (laying of polymer special-shaped waterproof board → lap joint treatment → laying of rainwater collection pipes → simultaneous installation of integrated control circuit system for auxiliary siphon drainage pipes) → self-inspection and acceptance → inspection and acceptance.

special-shaped waterproof board → lap joint treatment → laying of rainwater collection pipes → simultaneous installation of integrated control circuit system for auxiliary siphon drainage pipes) → self-inspection and acceptance → inspection and acceptance.

3.3.1 Acceptance and cleaning of the base

The base meets the design and specification requirements. Party A shall conduct quality acceptance of the previous project and construction can only be carried out after passing the inspection. The surface of the base has been cleaned and is basically flat, with no obvious protruding parts. The base is shot blasted by a shot blasting machine, and defective parts should be repaired.

3.3.2 Waterproofing construction

1) Preparation of waterproof coating

Pour the cold-applied non-curing rubber asphalt waterproof coating component A and B into the mixing bucket according to the mass ratio (1:2) required by the instructions, and stir them evenly mechanically. The mixed coating should be used up within 2 hours.

2) Detailed node treatment

2) Detailed node treatment

The node parts are treated with cold-applied non-curing rubber asphalt waterproof coating, and polyester non-woven fabric or mesh cloth is added for reinforcement. The width of the reinforcement layer is 300~500mm, and the coating is required to penetrate the polyester non-woven fabric or mesh cloth.

3) Coating and roll composite construction

Cold-applied non-curing rubber asphalt waterproof coating and ultra-fiber polymer membrane-based double-sided self-adhesive root-resistant waterproof membrane should be constructed simultaneously. The long and short sides of the membrane are overlapped by the body self-adhesive, and the overlap width is 80mm. The air under the membrane should be exhausted to make the membrane and the coating firmly adhered. The vertical surface closing should be supplemented with pressure strips or cement nails for mechanical fixation, and the seam sealing and protection measures should be taken. Damage to the waterproof layer is strictly prohibited.

3.3.3 Construction of polymer special-shaped waterproof sheet

Remove the surface isolation film of the double-sided self-adhesive root-piercing waterproof roll based on the microfiber polymer membrane, roll the polymer special-shaped waterproof sheet to make the waterproof sheet and the roll firmly adhered.

The long and short sides of the polymer special-shaped waterproof sheet are overlapped by hot air welding. The long side overlap seam should be welded first, and then the short side overlap seam.

The long and short side welding seams are constructed by automatic hot air welding machine. The parts that cannot be welded by the automatic welding machine and the special node parts are welded by manual welding gun. The effective welding width is >30mm, and the effective welding width of the detailed nodes is >10 mm.

3.3.4 Installation of rainwater collection pipe

According to the pipe layout construction design drawing, the line is positioned to determine the direction and position of the rainwater collection pipe. The rainwater collection pipe should be arranged in the blank area reserved by the concave and convex drainage board. After the rainwater collection pipe is installed, the ventilation pipe is installed.

3.3.5 Install the auxiliary siphon small tube and the fully automatic control system

The direction and position of the auxiliary siphon small tube shall be determined according to the pipe layout construction drawing. The auxiliary siphon small tube and the fully automatic control system shall be installed synchronously. The pipes shall be hot-melt butt joint or capacitor welding. The connection shall be tight and firm, and the misalignment shall not exceed 10% of the wall thickness.

According to the coordinates of the lowest point position marked on the drawing, the observation well shall be built with a height of 200mm higher than the planting soil layer. The bottom of the observation well shall be hollow masonry with a diameter of 600~1000mm, and the outside shall be wrapped with non-woven fabric to form a filter layer.

3.4 Key points and difficulties of the project

The key points and difficulties of this project are mainly the laying and welding construction of polymer special-shaped waterproof sheets. Compared with traditional waterproof materials, polymer special-shaped waterproof sheets are not easy to operate due to the influence of materials and shapes, and the construction is more difficult; compared with the traditional drainage board construction process of buckling or overlapping, the polymer special-shaped waterproof sheets need to be welded into a whole in this project, which not only has requirements for materials and design, but also has higher requirements for the skills and on-site management level of the operators.

3.4.1 Long/short side overlap

1) Long side situation 1: Rainwater collection pipes need to be laid in this area

After the polymer special-shaped waterproof sheet is welded, the blank position is used to lay the rainwater collection pipe. The rainwater collection pipe is bonded/fixed with double-sided butyl tape. After the rainwater collection pipe is laid, it should be covered with a 500mm wide anti-collapse microfiber water filter cloth on the top. The overlap of the water filter cloth can be bonded with a transparent adhesive, as shown in Figure 4.

2) Long side situation 2: Rainwater collection pipes do not need to be laid in this area

After the polymer special-shaped waterproof sheet is welded, the blank position needs to be covered with a waterproof sheet of the same material, as shown in Figure 5. After the overlap is welded, a 220~240mm wide polymer special-shaped waterproof sheet should be cut for seam covering, and a 500mm wide anti-collapse microfiber water filter cloth should be covered on the top. The overlap of the water filter cloth can be bonded with a transparent adhesive.

3) Short side situation 1: Rainwater collection pipes need to be laid in this part

When the short side of the polymer special-shaped waterproof board is overlapped, a 150mm wide and 1.2mm thick polymer special-shaped sheet of the same material (hereinafter referred to as a special homogeneous sheet) is used for docking and hot air welding. The effective welding width of the overlap seam is ≥30 mm. After welding, the total width of the short side is 200~220mm. The rainwater collection pipe is bonded/fixed with double-sided butyl tape. After the rainwater collection pipe is laid, it should be covered with a 500mm wide anti-collapse microfiber water filter cloth. The overlap of the water filter cloth can be bonded with a transparent adhesive, as shown in Figure 6.

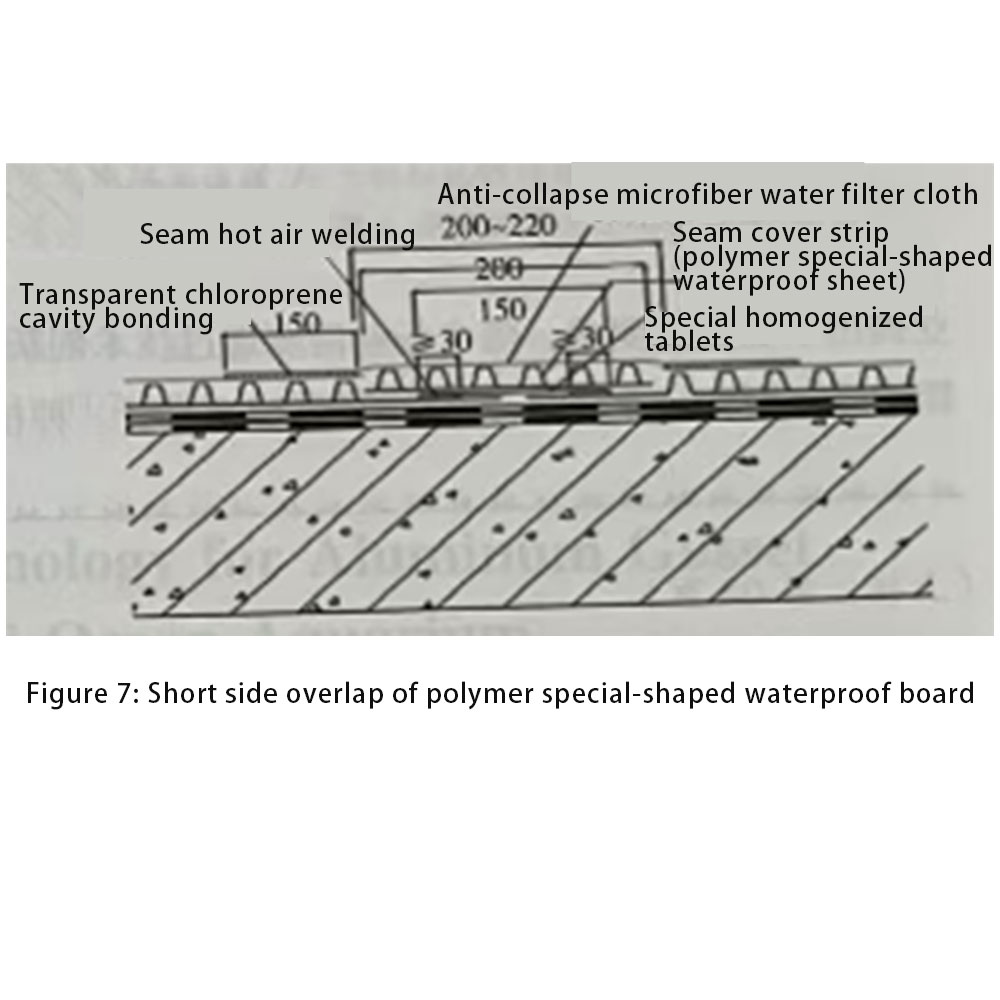

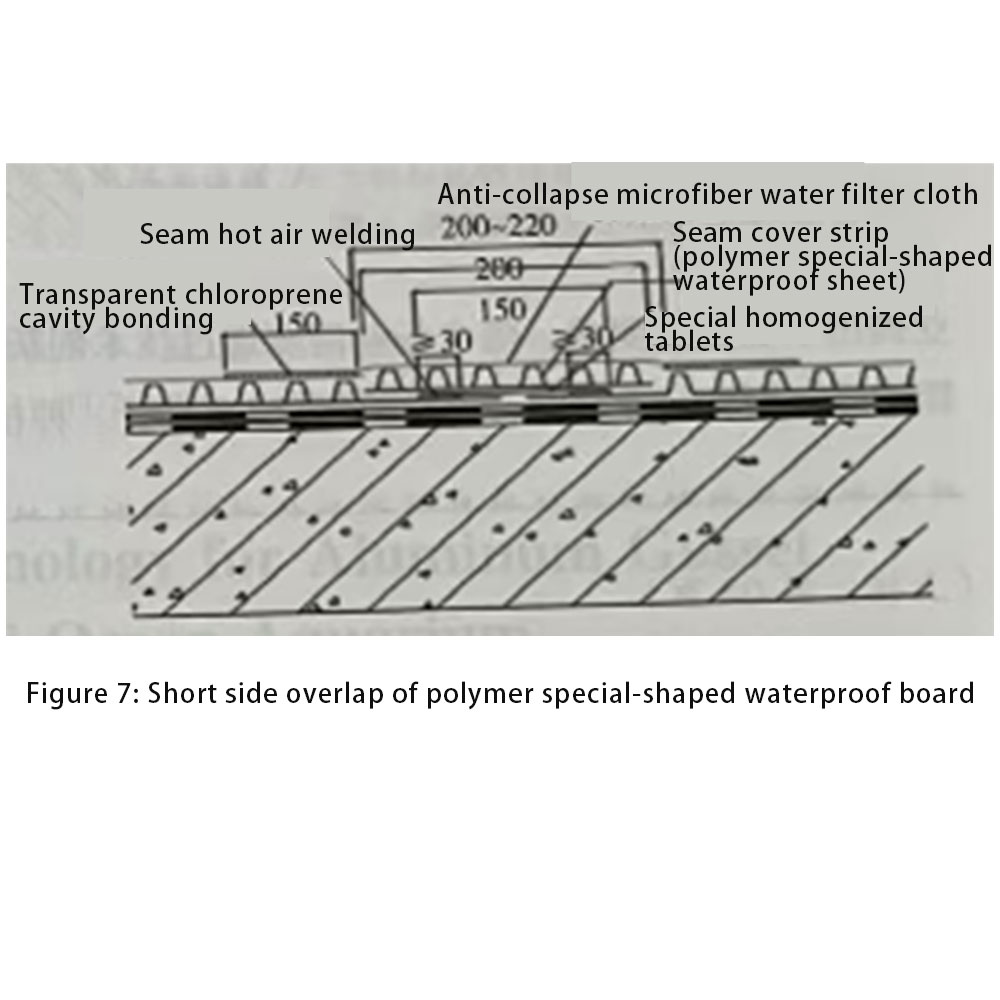

4) Short side situation 2: Rainwater collection pipes do not need to be laid on the short side

When the short side of the polymer special-shaped waterproof board is overlapped, a 150mm wide and 1.2mm thick special homogeneous sheet is used for docking and hot air welding. The effective welding width of the overlap seam is ≥30mm. After welding, the total width of the short side is 200~220mm. After the short side overlap is welded, a polymer special-shaped waterproof board with a width of about 200mm should be cut for seam covering, and a 500mm wide anti-collapse microfiber filter cloth should be covered on top. The overlap of the filter cloth can be bonded with a transparent adhesive, as shown in Figure 7.

3.4.2 Flip on the vertical wall

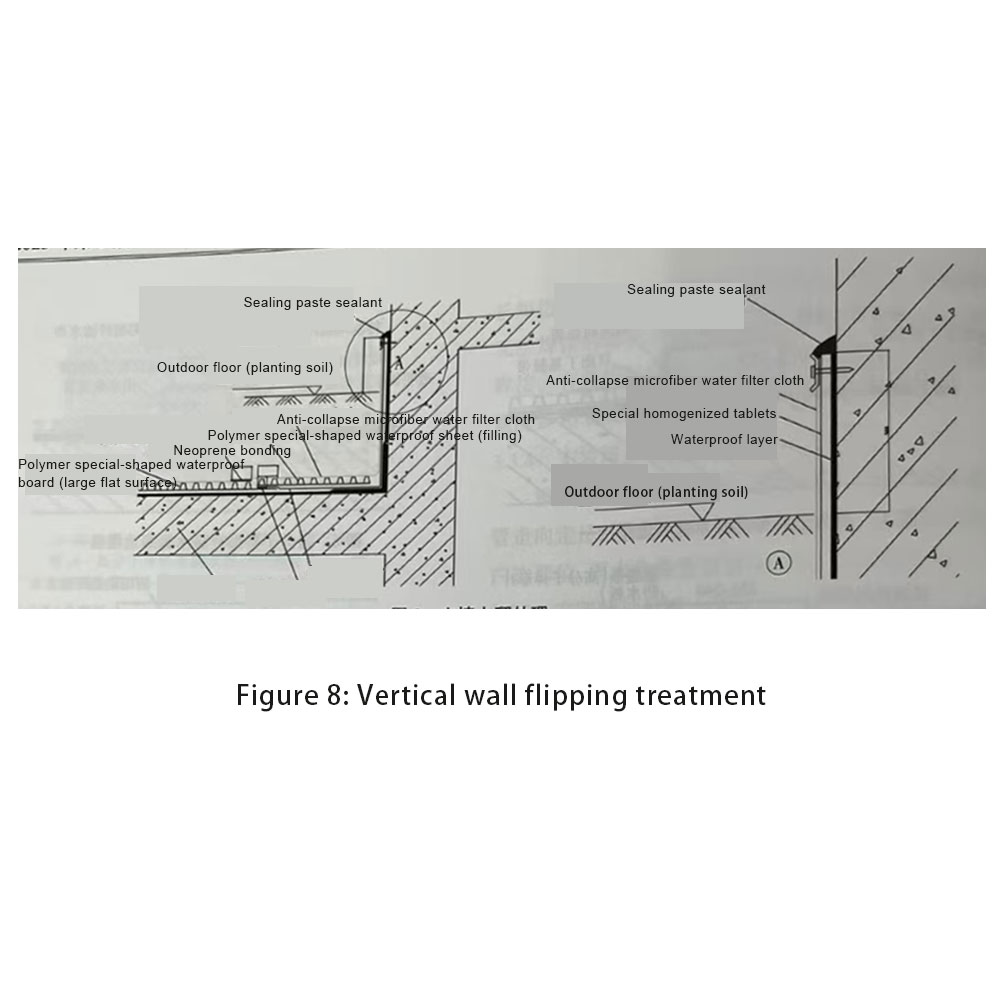

The flat part of the top plate is laid with a polymer special-shaped waterproof board to 500mm of the vertical wall, and

![]() the flip part of the vertical wall is laid with a 1.2mm thick special homogeneous sheet. The overlap of the special homogeneous sheet and the polymer special-shaped waterproof board is hot air welding, with a lap width of 100mm and an effective welding width of ≥30mm. The closing height of the special homogeneous sheet on the vertical wall should be 500mm higher than the planting soil, and it should be firmly bonded to the roll material layer below. For the blank parts of the plane, the polymer special-shaped waterproof sheet should be used to fill the base of the vertical wall, and then the anti-collapse microfiber water filter cloth should be laid on it separately. The water filter cloth and the water filter cloth of the polymer special-shaped waterproof sheet are overlapped by 150mm and bonded with transparent chloroprene adhesive. See Figure 8 for details.

the flip part of the vertical wall is laid with a 1.2mm thick special homogeneous sheet. The overlap of the special homogeneous sheet and the polymer special-shaped waterproof board is hot air welding, with a lap width of 100mm and an effective welding width of ≥30mm. The closing height of the special homogeneous sheet on the vertical wall should be 500mm higher than the planting soil, and it should be firmly bonded to the roll material layer below. For the blank parts of the plane, the polymer special-shaped waterproof sheet should be used to fill the base of the vertical wall, and then the anti-collapse microfiber water filter cloth should be laid on it separately. The water filter cloth and the water filter cloth of the polymer special-shaped waterproof sheet are overlapped by 150mm and bonded with transparent chloroprene adhesive. See Figure 8 for details.

3.4.3 Treatment of nodes such as three-dimensional Yin/yang corners and corners on the vertical wall

The nodes such as the flip corners, three-dimensional Yin/yang corners, and through-wall pipes on the vertical wall are all made of special homogeneous sheets as reinforcement layers, and are laid by welding technology. 3.5 Application effect

Since the completion of this project, there has been no building leakage, the drainage of each drainage outlet is in good condition, the control equipment operates normally, and the plants grow normally, meeting the original design requirements.

4. Conclusion

The acceleration of urbanization and the introduction of smart cities have put forward higher requirements for the waterproofing industry. The waterproofing industry needs to actively move closer to smart cities through technological innovation, intelligent applications and industry exchanges. The integrated drainage system for planting roof is a successful attempt by the waterproofing industry to move closer to smart cities.