1.Project Overview The Jinhua Auto Parts Industrial Park project is one of Zhejiang Province's major industrial projects, located in Jinyi District, Jinhua City, covering an area of 705.57 acres and a building area of approximately 880,000 m². The project mainly includes a combined plant, painting workshop, final assembly workshop, battery pack workshop, trial production and quality center, vehicle dispatch center, energy center, wastewater treatment plant, and oil, chemical, and hazardous waste storage facilities, all with metal roofs covering an area of up to 200,000 m².

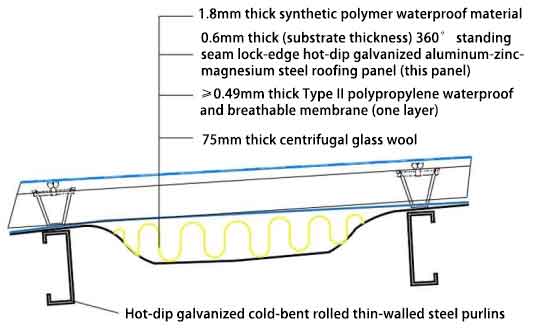

The roof structure design of this project, from bottom to top, consists of: 1) hot-dip galvanized cold-formed rolled thin-walled steel purlins; 2) 75 mm thick centrifugal glass wool, with a density of 16 kg/m³ and a thermal conductivity ≤0.039 W/(m·K); 3) a layer of type II polypropylene waterproof and breathable membrane with a thickness of not less than 0.49 mm; 4) a 0.6 mm thick (substrate thickness) 360° standing seam hot-dip aluminum-zinc-magnesium steel roofing panel (main panel); 5) a 1.8 mm thick synthetic polymer waterproof material. See Figure 1.

Figure 1. Hierarchical design of metal roof structure

2. Roof waterproofing design and material selection

2.1 Selection of Waterproofing Materials The selection of waterproofing materials for metal roofs should not only consider their compliance with current national standards, waterproofing quality, and waterproofing effect, but also the conditions of the metal substrate, so that the bonding performance and construction performance of the flexible waterproofing material can be perfectly matched with the metal roof panel.

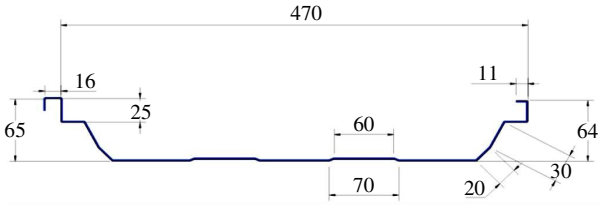

The roof panels used in this project are hot-dip aluminum zinc magnesium steel roof panels. The panel type is 470, with a flat unfolded width of 600 mm. After being pressed by a special tile press, the effective width is 470 mm. The moment of inertia of the section is 14.31 mm, and the section modulus is 6.02 mm, as shown in Figure 2.

Figure 2. Construction of 470mm hot-dip aluminum-zinc-magnesium steel roof panels

The 470 panel type differs from the 840 panel type, which has a risk of leakage due to self-tapping screw penetration. Its characteristics are:

1) The panel surface does not require screw penetration for fixation. The roof uses a standing seam design, allowing the roof panels to be firmly locked together, forming an integrated roof system that effectively prevents water seepage. However, for some detailed structural connections, such as the ridge, skylights, and gutters, a sealed connection cannot be formed between the steel plates; therefore, sloped drainage is still the primary method.

2) The standing seam design fully demonstrates its functional superiority, effectively solving the temperature stress problem caused by large temperature differences in the roof. Its thermal expansion and contraction compensation function is strong, preventing significant deformation due to large temperature differences.

3) Thermal insulation pads are installed at the supports to prevent cold bridging inside the roof, improving thermal insulation and energy-saving effects.

After communicating with the project design, client, general contractor and other parties, and comparing the performance of various polymer waterproof materials and the actual on-site sampling effects, 1.8 mm thick fiber-backed PVC waterproof membrane (L type) was finally selected as the flexible waterproof material, and the construction process adopted the full adhesion method.

2.2 Introduction to Main Materials

2.2.1 PVC Waterproof Membrane with Fiber Backing (Type L)

PVC waterproof membrane is a polymer waterproof membrane made primarily of polyvinyl chloride resin, with the addition of various chemical additives, and processed through complex processes such as mixing, extrusion molding, and vulcanization. Since its inception in 1963, PVC waterproof membrane has been used in projects worldwide under diverse climates and sunlight conditions, boasting over 55 years of proven service life.

In the standard "Polyvinyl Chloride (PVC) Waterproof Membrane" (GB 12952—2011), PVC waterproof membranes are classified into five categories based on their composition: homogeneous (H), fiber-backed (L), fabric-reinforced (P), glass fiber-reinforced (G), and glass fiber-reinforced with fiber backing (GL). Category L refers to PVC waterproof membrane with a fiber backing, where fabric is laminated to the underside of the membrane, and during construction, it is firmly bonded to the roofing substrate using a special adhesive.

This project uses 1.8 mm thick fiber-backed PVC waterproof membrane (exposed type), which features high tensile strength, high elongation, low shrinkage, and long service life. It also has excellent solar reflectivity, which can effectively reduce the rate of roof temperature rise. At the same time, the artificial climate accelerated aging time index exceeds 6,000 hours, which is far higher than the 2,500 hours specified in GB 12952—2011, providing a stronger guarantee for the long-term exposed use of the material.

2.2.2 PVC-Specific Adhesives

PVC-specific adhesives are soft, specialized adhesives formulated with natural rubber, resin, and solvents as the main raw materials, and incorporating various special polymer materials as a reinforcing system. They are characterized by rapid drying, high bonding strength, high solids content, water resistance, corrosion resistance, and room temperature curing. This adhesive is professionally used for bonding backed PVC waterproof membranes to concrete surfaces, steel, and other materials. It features moderate viscosity, long working time, and high bonding strength, and is widely used in the waterproofing industry. The applicable standard is "Polymer Waterproof Membrane Adhesives" (JC/T 863—2011).

2.3 Other Materials

Other materials include auxiliary materials, mainly: U-shaped pressure strips, edge sealing strips, silicone sealant, etc.

3. Construction Process

3.1 Construction Flow: Metal roof substrate cleaning → Marking and positioning → Pre-laying of roofing membrane → Applying adhesive → Large-area PVC waterproof membrane application → Hot air welding (overlap treatment) → Detail and joint treatment → Inspection and acceptance.

3.2 Metal Roof Substrate Cleaning: Clean the substrate with a damp cloth or mop, removing any loose dust from the steel plate substrate to ensure a clean and tidy substrate before membrane application.

3.3 Marking and Positioning: Based on the membrane width, the roof's on-site dimensions, and the height of surrounding walls, lay out and mark the positioning lines to avoid problems such as tilting, insufficient overlap, or excessive overlap during membrane application.

3.4 Pre-laying of Roofing Membrane: After unrolling the entire membrane, pre-lay the membrane systematically along the marked lines. The roll material should be flat, straight, and loose, and should not be folded. This is to prevent wrinkles during subsequent welding of the roll material, and also to avoid shrinkage of the pasted roll material due to internal stress, thus facilitating the subsequent application of the roll material.

3.5 Applying PVC roll material adhesive

1) When applying adhesive, ensure that both the substrate and the fiber-backed side of the roll material are coated. If the substrate is oily, it can be cleaned with acetone.

2) First, rewind the roll material. When applying adhesive, ensure that no areas are missed. The theoretical amount of adhesive used is 0.4~0.5 kg/m². Due to labor losses and other reasons, the average amount of adhesive used in this project is 0.55 kg/m².

3) After laying out and aligning, fold the roll material along the center line to one side. Use a scraper or glue roller to apply the adhesive to the roll material and the bonding substrate. The drying time after applying the adhesive depends largely on the weather conditions, the load-bearing layer, and the amount of adhesive used [3]. Under normal circumstances, the substrate and the roll material should be evenly coated with adhesive and allowed to dry for 10~20 minutes. After the adhesive is no longer sticky to the touch, press and bond the roll material.

3.6 Laying the Roofing Membrane

1) After the adhesive has dried, lay the roofing membrane on the bonding substrate and compact it with a hand roller. Repeat the above steps for the remaining membrane.

2) For full-coverage roofing membranes, lay them along the long side of the metal sheet, working from lower to higher elevations. Overlap the long sides of the membrane with an 80 mm overlap, preferably in the direction of water flow. Butt-joint the short sides, covering the joint with a 150 mm wide strip of homogeneous (H) type membrane. The overlaps between adjacent membrane sheets should be staggered by at least 500 mm.

3.7 Hot Air Welding (Overlap Treatment)

Welding methods are divided into two types: 1) Automatic welding, generally used for large-area welding and areas easily accessible by automatic welding machines; 2) Manual welding, generally used for welding detailed nodes and complex areas that are difficult to reach by manual welding machines, serving as an auxiliary welding method.

3.7.1 Operation Procedures

1) Automatic Welding Operation Procedure: Adjust the overlap width of the coil material → Adjust the welding machine parameters → Preheat the welding machine → Clean the overlap edge → Weld → Inspect the weld.

2) Manual Welding Operation Procedure: Determine the welding position → Adjust the handheld welding torch parameters → Preheat the welding machine → Clean the overlap edge → Spot weld → Pre-weld → Actual weld → Inspect the weld.

3.7.2 Precautions

1) Trial Welding: A trial weld is required before actual welding. For automatic welding, adjust the welding machine parameters according to the actual situation, perform a trial weld, observe the peeling effect until it meets the requirements, and record the values; for handheld welding torches, adjust the welding torch parameters or settings, and perform a trial weld. After the trial weld, a sample should be sealed and retained.

2) Large-Surface Welding: Before welding, clean the overlap edge with a special cleaning agent to ensure a more reliable weld. The long side is welded using a climbing welding machine, with an overlap width of 80 mm; the short side is welded using a handheld welding gun, and the short side is treated with a homogeneous (H) class PVC sheet cover strip, with a cover strip width of 150 mm.

3.8 Details and Joint Treatment

3.8.1 Detail Treatment

T-shaped overlaps should use a reinforcing layer and beveling treatment. The reinforcing layer should be a homogeneous polymer waterproof membrane of the same material. The diameter of the circular reinforcing layer should not be less than 150 mm; the corners of the rectangular reinforcing layer should be smooth rounded corners. The beveling treatment should be performed by using a scraper to cut the weld front end of the membrane edge into a bevel, and the beveling area should be larger than the welding area.

3.8.2 Joint Treatment

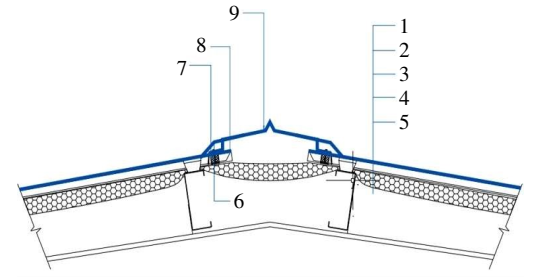

1) Ridge Treatment: Cut the appropriate amount of membrane according to the width of the ridge cover plate, apply full adhesion, then cut at the crest of the metal plate. Finally, reinforce the junction of the metal plate and the roof cover plate by cutting an oval-shaped membrane according to the site dimensions for reinforcement. Figure 3 shows the reinforced waterproofing method for the roof ridge and its on-site effect.

1—1.8 Thick PVC waterproof membrane with fiber backing (Type L); 2—0.6 Thick (substrate thickness) 360° standing seam lock-edge hot-dip aluminum zinc magnesium steel roofing panel (this panel); 3—≥0.49 Thick Type II polypropylene waterproof and breathable membrane; 4—75 Thick centrifugal glass wool; 5—Hot-dip galvanized cold-bent rolled thin-walled steel purlin; 6—Oval patch; 7—Metal external end cap; 8—Wave fold; 9—Ridge cover plate (20mm wide overlap with 2 layers of 5mm thick butyl rubber).

Figure 3. Reinforced waterproofing method for the roof ridge and its effect on site.

2) Parapet wall treatment: The roofing membrane at the parapet wall should be turned up at least 250 mm, and the end should be fixed with a sealing strip and sealed with sealant; the junction of the vertical and horizontal surfaces should be fixed with a U-shaped strip, and covered with a 150 mm wide homogeneous (Class H) cover strip and welded tightly. The waterproofing reinforcement method and on-site effect at the parapet wall are shown in Figure 4.

1—1.8 Thick PVC waterproof membrane with fiber backing (Class L); 2—0.6 Thick (substrate thickness) 360° standing seam lock-edge hot-dip aluminum-zinc-magnesium steel roofing panel (main panel); 3—≥0.49 Thick Type II polypropylene waterproof and breathable membrane; 4—75 Thick centrifugal glass wool; 5—Hot-dip galvanized cold-bent rolled thin-walled steel purlins; 6—U-shaped pressure strip; 7—Class H homogeneous cover strip; 8—Wall panel; 9—Edge sealing strip; 10—Silicone weather-resistant sealant; 11—Cap.

Figure 4. Waterproofing reinforcement method and on-site effect at the parapet wall

3) Treatment of flat skylights: When laying the roofing membrane, extend it to the perimeter of the skylight and secure it fully. Leave a certain distance (the upward curve distance of the flat roof skylight edge) of not less than 30 mm on the side parallel to the roof panel crest, and fix it with a strip. Seal the side perpendicular to the roof panel crest with weather-resistant silicone sealant. The waterproofing method and on-site effect of the flat skylight are shown in Figure 5.

Figure 5. Waterproofing method and on-site effect for flat skylights

4) Gutter Treatment: The project uses stainless steel gutters, which are strong, durable, and resistant to rust and corrosion, providing excellent drainage. Furthermore, the stainless steel gutters are welded at the overlaps, requiring a layer of silicone structural sealant as a reinforcement. Silicone structural sealant offers excellent weather resistance and adhesion, resisting rainwater erosion.

3.9 Inspection and Acceptance

1) Check that the membrane is laid flat and straight, without wrinkles or bends.

2) Use a machine or hook to inspect the overlaps, ensuring that each weld is properly sealed and free of defects or leaks. Any defects or leaks should be repaired immediately.

3) Protect the completed work surface from damage.

3.10 Summary of Construction Experience

1) Good compatibility between different materials in contact is essential; for example, adhesives and waterproof membranes must have good compatibility. It is best to choose the manufacturer's matching adhesive to avoid incompatibility issues between the adhesive and the waterproof membrane. If other adhesives are used, it is recommended to conduct a small-scale bonding test before use to avoid problems such as poor adhesion or incompatibility later.

2) During construction, attention should be paid to the amount, thickness, and uniformity of the adhesive, as these factors will affect the final bonding effect. Uneven application of adhesive, excessive or insufficient amount of adhesive will affect the final bonding effect. The amount should be based on the construction guidance of the adhesive manufacturer, with appropriate deviations according to the condition of the substrate and labor loss.

3) A professional polymer membrane construction team should be selected. After completion, the welding quality should be inspected, and timely remedial measures should be taken if any false welds or leaks are found.

4) Due to the use of different materials for connecting details, such as the connection between the parapet wall and the gutter made of steel plate, and the roof skylight and other protruding parts of the roof, the stress changes of different materials are not synchronized, which can lead to loosening of the joints and rainwater directly entering the interior of the building [4]. Therefore, detailed details such as gutters, skylights, parapet walls, and roof-mounted equipment should be subject to specialized construction plans prepared according to the design specifications. These plans should include specific construction steps and schematic diagrams of the details. Professional construction personnel should be selected to complete the construction and perform maintenance.

4. Conclusion

This project involves the full adhesion of 1.8 mm thick fiber-backed PVC waterproof membrane (Class L) to the 470mm hot-dip galvanized aluminum-zinc-magnesium steel roof slab. The waterproofing level is Class I, meeting the requirements of the "General Specification for Waterproofing of Building and Municipal Engineering" (GB 55030—2022). Through material testing and selection, and the screening of supporting materials such as PVC-specific adhesives, this project overcame challenges such as the difficulty of constructing the waterproof layer at the 470mm outer panel seam and the bonding between the 470mm outer panel and the PVC waterproof membrane, creating a roof system that perfectly combines rigid and flexible waterproofing.