01 Project Overview

This new energy and environmentally friendly waste-to-energy incineration power plant project in Shandong Province covers an area of 80 mu (approximately 1,000 acres) and primarily consists of a comprehensive office building, workshops, and ancillary facilities.Upon completion,the project will process 18.25 tons of waste annually and generate 72.45 million kW of electricity annually.The workshop roof,with a metal base covering approximately 5,000 square meters, will be constructed.This article describes the waterproofing design,material selection, and construction techniques for the metal roof.

02 Roof Waterproofing Design and Material Selection

2.1 Roof Structure Design

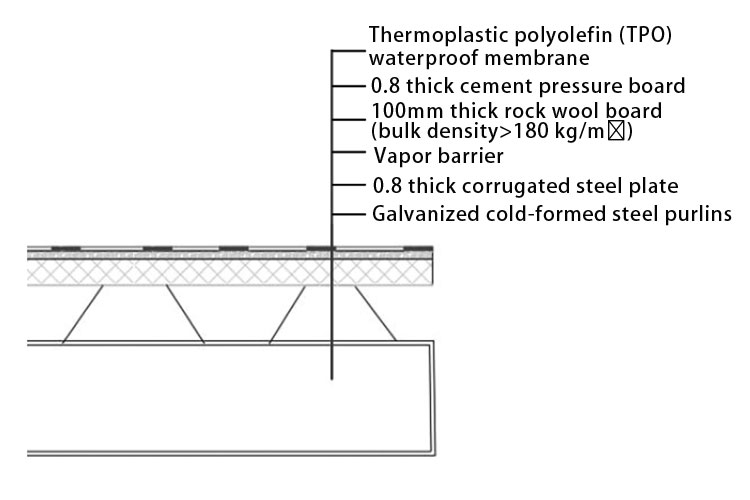

The waterproofing protection level of the metal roof of the workshop in this project is Class I.The original design roof structure, from bottom to top,consists of: roof purlins;Jinwu roof panels (sheet type YX 70-200-600);vapor barrier;100 mm thick rock wool board (bulk density ≥ 180 kg/m³);0.8 mm thick cement-pressed board;and thermoplastic polyolefin (TPO) waterproof membrane (Figure 1).

Figure 1 Original design roof structure of the project

2.2 Selection of Roof Waterproofing Layer

The main waterproofing material for this roof system was originally designed to be a single-layer thermoplastic polyolefin (TPO) waterproofing membrane.Taking into account the special characteristics of the roof of this project,a 1.5 mm thick butyl self-adhesive TPO waterproofing membrane was ultimately selected. After comprehensive consideration of the waterproofing level,project importance, waterproofing reliability, and durability,two layers of 1.5 mm thick butyl self-adhesive TPO waterproofing membrane were ultimately used as the roof waterproofing layer.

2.2.1 Advantages of double-layer butyl self-adhesive TPO waterproof membrane The factors affecting the reliability of the waterproof system are not only related to the life of the waterproof material itself,but also related to the construction method between the waterproof layers [1].Butyl self-adhesive TPO waterproof membrane is one of the most durable materials among the commonly used waterproof materials.Its key performance indicators include:impermeability of 0.6 MPa,impermeability for 2 hours,heat resistance of 100 ℃,low temperature performance of -40 ℃ without cracks,and maintaining the stability of various key physical properties in salt,acid,alkali and heat environments;the butyl self-adhesive TPO waterproof membrane forms a full adhesion effect with the base layer,and its anti-water leakage effect is excellent; the overlap edge adopts hot air welding,which is the most reliable method among the existing membrane overlap methods of hot melt, hot welding,self-adhesive,adhesive tape and adhesive.In the design of the double-layer flexible butyl self-adhesive TPO waterproof membrane system,the upper membrane has a better protective effect on the lower membrane. Water,light,heat,and other natural factors first act on the upper membrane,then gradually penetrate deeper into the membrane before finally invading and affecting the secondary membrane.Only after the upper membrane is damaged and fails can the lower membrane begin to independently withstand the effects of external factors.Therefore,compared to single-layer self-adhesive TPO waterproofing membranes or single-layer TPO waterproofing membrane designs,double-layer butyl self-adhesive TPO waterproofing membranes undoubtedly offer significantly improved waterproofing effectiveness and durability.

2.2.2 Construction and Application Advantages of Butyl Self-Adhesive TPO Waterproofing Membrane

1) Construction and Features

The 1.5 mm thick butyl self-adhesive TPO waterproofing membrane primarily consists of a 1.1 mm thick TPO sheet,a 0.4 mm thick refined butyl rubber self-adhesive layer,and an isolation layer.The TPO sheet complies with GB 27789-2011 "Thermoplastic Polyolefin Waterproofing Membrane,"and the self-adhesive layer complies with GB/T 23260-2009 "Waterproofing Membrane with Self-Adhesive Layer."The TPO sheet used in the self-adhesive membrane is a homogeneous TPO sheet made from high-quality Basel raw materials.All exposed performance indicators meet and exceed relevant standards,passing extended artificial climate accelerated aging tests (10,000 hours),with a solar reflectance of ≥0.78,a wind resistance test with a simulated wind pressure of 7.2 kPa, and flame retardancy of B2.

The butyl self-adhesive adhesive used in the self-adhesive membrane exhibits excellent high saturation,high creep resistance,and water and air tightness.Whether exposed to temperatures as high as 100°C,as low as -35°C,or even under prolonged water immersion, the butyl adhesive maintains its various physical properties. Furthermore, the butyl adhesive maintains stable performance during freeze-thaw and weathering tests in the laboratory,demonstrating exceptional durability.Butyl adhesive combined with TPO membrane enhances the membrane's aging,UV, and chemical resistance.It also provides a longer-lasting bond with the base layer,maintaining a consistent,"skin-like" full-bond effect and making the waterproof layer more durable.

When waterproof membranes are used exposed,their wind-tightness resistance must be considered. According to T/CCIAT 0028-2020,"Technical Specifications for Single-Ply Waterproof Membrane Roofing Systems,"during full-bond application, the peel strength between the membrane and the base layer should not be less than 30 N/50 mm.However, butyl self-adhesive TPO waterproof membranes can achieve a full-bond peel strength of up to 100 N/50 mm,ensuring wind-tightness resistance.

2) Application Advantages

① The self-adhesive layer of butyl self-adhesive TPO waterproof membranes is directly laminated and formed with the TPO sheet in the factory.This allows for greater control over the thickness,uniformity, and adhesion of the adhesive layer to the sheet during full-bond application,resulting in superior full-bond results.

② When constructing butyl self-adhesive TPO waterproofing membrane,the cold construction process of self-adhesive waterproofing membrane can be referred to,which makes the construction simpler and more convenient.At the same time, it avoids fire accidents caused by improper heating of other system materials such as insulation materials,making the construction safer.The efficiency of self-adhesive membrane construction is improved,which can save labor time and labor costs.

③ The node part is the place where leakage is prone to occur in the waterproof layer,and generally requires manual processing.Due to the influence of construction space,changes in the characteristics of the base layer,etc.,the advantages of using self-adhesive and adhesive tape to process the node part are more obvious [1].That is,in terms of the processing of detailed nodes,butyl self-adhesive TPO waterproofing membrane has more advantages.The waterproofing processing of details such as corners is simpler and can be cut according to the actual size,making the construction more convenient.

03 Roof Waterproofing System Construction

3.1 Construction Process

Cementitious Pressure Plate Base Preparation→Marking and Positioning→Large-Surface Application of First Layer of Butyl Self-Adhesive TPO Waterproofing Membrane→Hot Air Welding (Membrane Overlap Treatment)→Self-Inspection and Acceptance→Second Layer of Butyl Self-Adhesive TPO Waterproofing Membrane→Hot Air Welding (Membrane Overlap Treatment)→Detailed Joint Reinforcement Treatment→Self-Inspection and Repair.

3.2 Waterproofing Layer Construction

After the cementitious pressure plate construction is completed and accepted,waterproofing layer construction can be carried out.

3.2.1 Base Treatment Agent Selection and Treatment

1) Treatment Agent Selection

The base treatment agent must be compatible with the butyl self-adhesive TPO waterproofing membrane,meaning that there should be no harmful chemical reactions between the agent and the butyl adhesive.This project selected a butyl-based base treatment agent specifically designed for membranes.Composed of a polymer emulsion and multifunctional additives,it offers excellent sealing properties,strong permeability,high interfacial strength,and excellent bonding with butyl self-adhesive membranes.Furthermore,it does not form a film with the base layer,nor does it hinder the penetration of the butyl self-adhesive layer into the base layer.

2) Base Treatment

Clean the roof base (cement pressure board) and remove any oil,sharp objects,and other debris to ensure a clean and smooth surface.

3) Applying the Base Treatment Agent

Use a roller to apply the butyl-based base treatment agent specifically designed for membranes,ensuring complete and even coverage.Generally,a minimum of 0.2 kg of base treatment agent per 1 m² is sufficient.

3.2.2 Large-Scale Waterproofing Layer Application

1) Before laying the large-scale membrane,plan and arrange the layout based on the roof's shape and operating conditions.Align and set the baselines,and use marker lines for positioning.2) Before laying the first layer of waterproofing membrane,pre-lay the membrane to relieve the stress of the membrane rewinding.When laying the waterproofing membrane,begin laying the membrane in the direction of water flow on the roof,and then apply the overlapped joints step by step according to the reference line.

3) Secure the ends of the membrane.Gently cut the large-surface membrane with a paper cutter and lift the membrane, preferably at a 30° angle between the membrane and the membrane.Then, apply the self-adhesive membrane.While laying the membrane,another worker will use a roller to press the membrane from one side perpendicular to the long edge of the membrane to the other side,releasing air and ensuring a firm bond between the membrane and the substrate.Then, pre-lay the second membrane and align it with the overlap guide line of the first membrane, ensuring an overlap width of at least 80 mm. The application method is the same as for the first membrane.The short-side overlaps of two adjacent membranes on the same layer should be staggered by at least 500 mm.

4) The overlapping edges of the membranes are welded using hot air to ensure a secure bond even when exposed to the elements for extended periods.

01

Large surfaces are welded using an automatic welder.The process is as follows:adjust the overlap width of the coil→clean the overlap edge with a special cleaning agent→set welding parameters→preheat the welder→weld→inspect the weld. Detailed details are welded using a manual welding torch.The process is as follows:adjust the overlap width of the coil→ clean the overlap edge with a special cleaning agent→set welding parameters→preheat the welder→spot weld→pre-weld→final weld→inspect the weld.Manual welding is generally performed in three steps: spot welding,pre-weld,and final weld.

Spot welding:To prevent the coil from shifting,spot welds should be used to secure the overlap before welding the overlap.

Pre-weld:When welding the rear of the overlap, leave a 35 mm opening when using a 40 mm nozzle for the final weld. Keep the pressure roller and nozzle parallel during pre-weld.

Final weld: During this step, the pressure roller should move parallel to the nozzle exhaust port,30 mm from the nozzle. The pressure roller should always maintain full pressure on the mating surface.

02

The lap width on the long side is 80 mm,with an effective weld width of ≥ 25 mm.

03

The short sides of the membrane are butt-jointed using 150 mm wide homogeneous TPO waterproofing membrane.Each membrane is welded to the butt strips separately,with an effective weld width of ≥ 25 mm on each side.The overlap between adjacent membranes should be staggered by at least 300 mm.

04

Welding should be performed in an environment with a temperature above 5°C.The overlap must be kept dry and clean (if the ambient temperature is below 5°C,the weld must be preheated).

05

The second layer of waterproofing membrane is laid and overlapped in the same manner as the first layer;however, the joints between the upper and lower membranes should be staggered by 1/3 to 1/2 of the membrane width,and the two membranes must not be laid perpendicular to each other.

06

Conduct a self-inspection of the waterproofing layer and organize acceptance inspection.

3.3 Detailed Joint Treatment

Detailed joints should be welded manually.T-joints should be beveled.Use a trimming knife to bevel the front edge of the weld at the edge of the membrane.The beveled area should be larger than the welded area.The additional layer should be a homogeneous TPO waterproofing membrane of the same material.The diameter of the circular additional layer should be no less than 120 mm;the corners of the rectangular additional layer should be smoothly rounded.

1) Parapet:Following the self-adhesive membrane waterproofing method,first lay a 500 mm wide additional layer,then proceed with the large-surface installation,folding the wall 500 mm upwards.Secure with a closing strip and seal with sealant (Figure 2).

Figure 2 Parapet waterproofing

2) Expansion Joint Treatment:Butyl self-adhesive TPO membrane has excellent extensibility.The large-surface butyl self-adhesive TPO membrane is split at the expansion joint and secured on both sides with U-shaped strips.A PE rod is placed in the center of the expansion joint.A separate H-shaped TPO waterproofing membrane is then applied to cover the expansion joint and welded to the large-surface butyl self-adhesive TPO membrane.The width of H-type TPO waterproofing membrane at expansion joints should be no less than 300 mm + a (a is the expansion joint width) (Figure 3).

1—U-shaped strip; 2—foam rod; 3—foamed polyurethane filling; 4—TPO waterproofing membrane (H-type); 5—reinforced steel plate; 6—butyl self-adhesive TPO waterproofing membrane.

Figure 3 Waterproof treatment of expansion joints

3) Roof Exit Ducts: Use H-type TPO membrane for roof exit ducts. The upper end should be tightened with a stainless steel hoop and sealed with sealant. The height should be no less than 250 mm,and the lower end should be welded to the larger membrane (Figure 4).

Figure 4: Waterproofing of roof pipes

4) Roof Exit Skylights:TPO membrane should be applied to the facade of the skylight.The membrane should be attached to the upper edge of the skylight frame,along the flat surface of the square channel,or on the inner facade.Weather-resistant sealant should be used to seal the membrane.The lower end of the facade membrane should be welded to the flat membrane (Figure 5).

Figure 5 Waterproofing of roof skylights

5) Vertical Drain: Weld the H-type TPO waterproofing membrane into a cylindrical shape and place it inside the rainwater pipe.The lower end should be sealed with silicone sealant,and the upper end should be hot-air welded to the roof waterproofing layer (Figure 6).

Figure 6 Waterproofing of downspouts

6) Ridge:The butyl self-adhesive waterproofing membrane is laid and disconnected at the ridge.The middle part is filled with foam plastic to ensure the thermal insulation effect. Then,a piece of H-type TPO membrane with a width of about 650 mm (200 mm wider than the ridge board) is cut to cover the ridge board.The two sides are welded to the large-surface membrane.The specific node design is shown in Figure 7.

Figure 7 Waterproofing method at the ridge

04 Problem Discussion

During the implementation of this project,we received the attention and cooperation of all collaborating parties.Through design optimization,careful material selection,and standardized construction,we ensured project quality and met project expectations.This project has provided valuable experience in the application of butyl self-adhesive TPO waterproofing membranes on metal roofs and has also provided new insights into their further promotion and application.

First,the waterproofing structure of a specific roofing project should be specifically designed and selected by a specialized waterproofing company,including the performance requirements of the waterproofing membrane and the selection of construction techniques.The initial design for this project referenced a single-layer waterproofing membrane roof structure. However,for roofing projects with a typical construction structure of"purlin→corrugated steel sheet→vapor barrier→insulation layer→bonding base layer→waterproofing layer,"the design and application of a double-layer butyl self-adhesive TPO waterproofing membrane can more effectively improve the durability and reliability of the waterproofing project.

Second,the successful application of self-adhesive membranes such as butyl self-adhesive TPO waterproofing membranes in roofing construction requires a base structure that can strongly bond to the membrane,such as the fireproof overlay cementitious pressure plate used in this project.In general metal single-layer roof structures,the waterproof layer acts directly on the insulation layer.Therefore, more research is needed on the bonding base of butyl self-adhesive TPO membrane in the later stage, such as developing insulation materials that can directly produce strong bonding with butyl self-adhesive TPO membrane.